Why trucks are so expensive right now

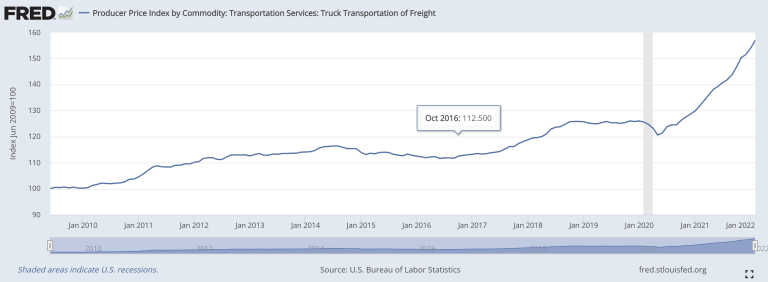

If you’re in the transportation world, you’ve seen inflation hit the market. It’s not just gas, it’s the price of our vehicles and prices of services that are so noticeable in our world. Take a look at this graph :

All of this can be scary, especially when Goldman Sachs lowered its forecast for annual U.S. economic growth, citing “higher oil prices,” and said there is a risk the United States will enter a recession in the next year.

Demand high, machines low

That being said, we all know goods still have to get to the table. Now it’s a question of what is getting the vehicle prices so high?

American Trucking Associations’ advanced seasonally adjusted (SA) For-Hire Truck Tonnage Index was unchanged in February after increasing 0.4% in January. In February, the index equaled 115.3 (2015=100) the same as January. ATA Truck Tonnage Index Unchanged in February | American Trucking Associations

Since the freight is about the same, it shows we are being choked by short supply. It’s impossible to move all of the freight truckers are being asked to move since there are not enough drivers and trucks.

Materials not being made/supply chain disruptions

According to DC Velocity who quoted ACT Research, “Low-cost manufacturing countries with low vaccination rates have had trouble in previous Covid waves. The Delta variant knocked Indian steel production off-line and disrupted automotive sub-assemblers in Southeast Asia. To combat Omicron, the Chinese government has instigated shelter-in-place quarantines, continuing their strict lockdown policy. As China remains the world’s workshop, Chinese parts suppliers and ports going off-line is a real short-term risk.”

And now with a new variant spreading through China, we might see even more of an impact on manufacturing. To put it into perspective, China manufactures about 69% of manufacturing in asia. COVID-19 Pandemic’s Effect on Manufacturing Industry | Pumps & Systems (pumpsandsystems.com)

Chips

1,000s of trucks are waiting unfinished in lots, waiting for chip enabled components. 10’s of 1,000s of trucks are waiting for repairs that require similar components. The chip shortage has had a huge impact on the manufacturing industry. To combat this, Intel is investing $20 billion to develop a new computer chip manufacturing plant in Ohio.

Ukraine

The affects of the Russian invasion is likely to be huge, according to CEO of Interact Analysis Adrian Lloyd. Russia produces the most natural gas globally, so manufacturers outside of the U.S. that supply the United States will be affected greatly.

Initial impact from kindness

The biggest and most obvious is the covid factor. Covid had a huge impact, shutting down many manufacturers in 2020. PACCAR and Navistar being just two examples of many. But these examples were out of precaution.

Removing lot’s of employees is easier than getting people back in. There were many who looked forward to getting back to work, but a contingent still have not returned. One can observe this trend in any city, where masses of “help wanted” signs everywhere.

Squeezing the amount of workers in factories and creating regulations makes returning to work difficult.

No one to drive

One part of the problem is the delivering of these vehicles across the country to get them out of lots. The usual strategic carriers have run low on their driver pool.

According to Mike Mulqueen, a partner at a transportation consulting firm, JBF, “the percentage of tenders going to the spot market for many shippers is up to 30 to 40 percent. Before the pandemic, it would have been less than 10 percent. JBF’s consulting practice is totally focused on freight transportation and TMS implementations.”

Vaccine mandate

Vaccine mandates are a huge issue for many americans for a plethora of reasons, including the right to self autonomy and personal health reasons. No matter the reason opposed to the vaccine, they are all opposed to mandating a vaccine.

Canada’s rules for U.S. drivers

In January of 2022, Canada banned U.S. and other foreign truckers from entering the country unless they are fully vaccinated. Canada will require non-vaccinated Canadian drivers to show a negative, Covid-19 test taken 72 hours prior to reaching the border before they are allowed entry. Those drivers will also have to quarantine for a 14-day period, which industry groups say will hurt fleets that are already short-staffed.

Summary

Freight trucks and vehicles in general are getting expensive and it’s due to several factors. Covid playing a huge role in minimizing work force, foreign plants not being able to create the material we need here, chip shortages, lack of drivers to transport vehicles and material, and natural gas production being choked due to covid and US reactions to Russia’s invasion.